The world of food technology is seeing a big change with a new printer that prints edible meat. This device is changing how we make food, offering a green way to produce meat. It also helps solve big food problems worldwide.

This printer can make high-quality meat, which is a big step forward in food tech. It brings together food tech and cooking innovation. This printer is set to change how we make and eat meat.

Introduction to Edible Meat Printing

Printing edible meat is an exciting idea. It could really change the food industry. By using food tech and cooking innovation, we can make food production better and more efficient.

Key Takeaways

- The printer that prints edible meat is a revolutionary device that transforms food production.

- Food technology and culinary innovation are driving forces behind this breakthrough.

- The printer offers a sustainable alternative to traditional meat production.

- It has the potential to address global food challenges.

- The device can produce high-quality meat products.

- It is poised to revolutionize the culinary world.

The Evolution of Food Technology: Why We Need a Printer That Prints Edible Meat

The world is facing a big challenge in meeting the growing demand for food, especially meat. With the global population expected to hit 9 billion by 2050, old ways of making meat are being questioned. They harm the environment and use up a lot of resources.

Innovative solutions are coming to tackle these issues. Food printing technology is one such answer. It makes high-quality meat products with less harm to the environment and better use of resources.

- Environmental concerns: Traditional meat making is a big source of greenhouse gas emissions and deforestation.

- Resource requirements: Meat making needs a lot of water, feed, and land. This puts a lot of pressure on the world’s resources.

- Health risks: Old ways of making meat can be bad for people’s health. This includes antibiotic resistance and foodborne illnesses.

Food printing technology is a hopeful answer to these problems. It lets us make meat products that are good for the planet and healthier. This technology helps us move away from old meat-making methods. It aims to make our food system more sustainable for the future.

Understanding How Meat Printing Technology Works

Meat printing technology is a new way to make meat products. It has many environmental benefits. This method uses cells to create meat, which means less land, water, and feed are needed.

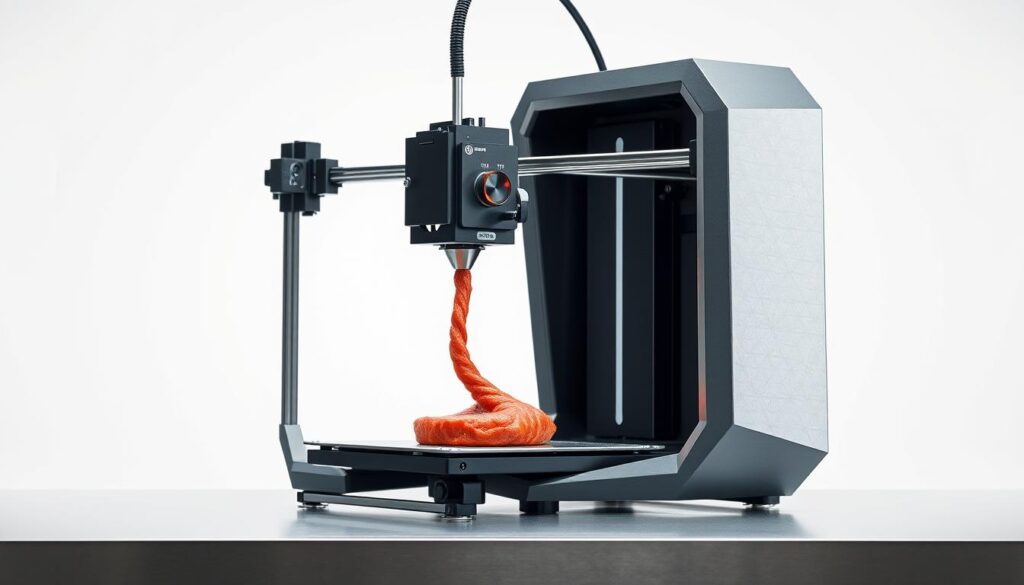

To make meat products, several steps are followed. First, bioink is made. It’s a mix of cells and nutrients for meat. Then, the printer is filled with bioink, and the printing starts. The printer adds layers of bioink to form the meat product’s shape and structure.

This technology can greatly help the environment. It cuts down on greenhouse gas emissions and uses less water. By not needing traditional livestock farming, it reduces the meat industry’s environmental harm.

- Reduced land use: Meat products are made in labs, not on large farms.

- Decreased water usage: This method uses much less water than raising livestock.

- Lower greenhouse gas emissions: Making meat this way produces fewer emissions than traditional farming.

In summary, meat printing technology is a green solution for making meat. It offers many benefits over traditional farming, like using less land, water, and producing fewer emissions.

The Science Behind Edible Meat Printing

Edible meat printing uses cells to make meat products with certain nutritional profiles. This method could change how we make and eat meat. It’s a greener and more efficient way than raising animals for food.

At the core of this tech is cellular agriculture. It uses cells to create meat products. This lets us make meat that’s not just tasty but also healthy.

Cellular Agriculture Basics

Cellular agriculture grows food from cells, not animals. It’s better for the planet because it uses less land, water, and makes less pollution.

Bioink Composition

Bioink is key in edible meat printing. It gives cells the nutrients they need to grow and change. The mix of bioink can change based on the type of cells and the product being made.

Printing Process Explained

The printing method puts bioink on a base and then uses heat or pressure to help cells grow. This method can make many types of meat, from ground meat to muscle tissue.

Nutritional Profile of Printed Meat Products

Printed meat products could change how we eat meat. They offer a nutritional profile that can be tailored to fit our dietary needs. The taste and texture of these products are key. They must feel and taste like real meat.

These products can be made to fit specific nutritional needs. For example, they can have less fat and more protein. This makes them great for those who care about their health. You can also adjust the taste and texture to match your preferences.

Here is a comparison of the nutritional profiles of traditional and printed meat products:

| Product | Protein Content | Fat Content |

|---|---|---|

| Traditional Meat | 20-30% | 30-40% |

| Printed Meat | 30-40% | 10-20% |

In conclusion, printed meat products are a game-changer. They let us create meals that are tailored to our health needs. With their ability to mimic the taste and texture of real meat, they offer a healthier and more sustainable choice.

Environmental Benefits and Sustainability Impact

Traditional meat production harms the environment a lot. It causes greenhouse gas emissions, pollutes water, and damages land. But, printed meat products are a better choice. They need less land for farming, which helps the planet.

This method also makes production cheaper. So, printed meat is more affordable than regular meat.

Printed meat has many advantages. For example:

- It has a lower carbon footprint because it uses less energy.

- It saves water, which is great for our planet.

- It uses land more efficiently, helping the environment.

In summary, printed meat is better for our planet. It’s cheaper to make and helps the environment. This makes it a key part of a sustainable food system for the future.

Current Market Applications and Available Models

The market for meat printers is growing fast. New companies and products keep coming out, thanks to food technology advances. This growth meets the demand for new culinary solutions. Now, you can find many meat printer models, from small desktop ones to big industrial ones.

Meat printers are used in commercial food production and research and development. They help make custom meat products and test new printing methods. They also help create new food items like plant-based meats and lab-grown meats.

Here are some examples of available models:

- Desktop printers for home use, such as the Novameat printer

- Commercial-scale printers for restaurants and food manufacturers, such as the Redefine Meat printer

- Industrial-scale printers for large-scale meat production, such as the Memphis Meats printer

These models let people and businesses try out meat printing. This drives more innovation in food technology and culinary innovation.

Comparing Traditional and Printed Meat: Taste, Texture, and Cost

The debate between traditional and printed meat has sparked intense interest in the food production industry. As consumers become more aware of the environmental benefits of alternative meat sources, the demand for sustainable options is on the rise. In the context of meat production, printed meat offers a promising solution.

When it comes to taste, printed meat can be tailored to mimic the flavor profile of traditional meat. This is achieved through the use of specific bioinks and printing techniques. In terms of texture, printed meat can also be adjusted to provide a similar sensory experience. The cost of printed meat is another critical factor, as it must be competitive with traditional meat products to be viable.

A key consideration in the comparison between traditional and printed meat is the environmental benefits of the latter. Printed meat production requires significantly less land, water, and feed than traditional meat production methods. This reduction in resource usage contributes to a more sustainable food system.

| Characteristics | Traditional Meat | Printed Meat |

|---|---|---|

| Taste | Natural flavor profile | Tailored flavor profile |

| Texture | Natural texture | Adjustable texture |

| Cost | Variable costs | Competitive costs |

| Environmental Impact | High resource usage | Low resource usage |

Home Usage and Consumer Adoption

Meat printing technology is getting cheaper and easier to use. Soon, people might start using meat printers at home. The nutritional profile of printed meat will be key. People will want it to be tasty, healthy, and good for the planet.

The taste of printed meat is also important. If it tastes like real meat, more people will try it. Using a meat printer at home has many benefits.

- Convenience: you can print meat whenever you want

- Customization: you can choose your favorite flavors and textures

- Cost-effective: it might be cheaper than buying meat from the store

As the tech improves, more people will use meat printers at home. It could change how we make and eat food. Meat printing could offer a nutritional profile and taste that’s just as good as traditional meat.

Conclusion: The Future of Food Production in Your Kitchen

The texture and cost of printed meat are getting better. This means the future of food in your kitchen is looking up. The printer that prints edible meat is a game-changer. It uses new tech to make meat alternatives at home.

This tech is all about making food in a better way. It’s good for the planet and gives us healthier food choices. As more people start using this tech, we’ll see even more options. This could change how we eat and live.

FAQ

What is a printer that prints edible meat?

A printer that prints edible meat is a new tech. It uses cells to make meat products. This method is better for the environment because it needs less land, water, and food.

How does meat printing technology work?

Meat printing uses cells to make meat. First, it creates bioink. Then, it loads the printer and prints the meat. The bioink must support cell growth and change.

What are the nutritional benefits of printed meat products?

Printed meat can be made healthier. It has more protein and good fats. It also has important nutrients.

What are the environmental benefits of using a printer that prints edible meat?

Printed meat is better for the planet. It uses less water and land. It also cuts down on carbon emissions.

How do printed meat products compare to traditional meat in terms of taste and texture?

Printed meat can taste and feel like real meat. Scientists work hard to make it just right. They want it to feel and taste like meat we’re used to.

What is the cost-benefit analysis of using a printer that prints edible meat?

The cost of printed meat is important. It must be affordable to compete with regular meat. But, the long-term benefits to the environment make it worth it.

What is the potential for home usage and consumer adoption of meat printers?

Meat printers could become common in homes. As they get cheaper, more people will use them. The taste, health benefits, and ease of use will decide if people want them.